Flexible automated production management system

In today's rapidly changing business environment, companies must constantly seek innovation and efficiency improvements in order to remain competitive. As an advanced manufacturing execution system, the core of the flexible automated production management system is to improve production efficiency while maintaining a high degree of flexibility and adaptability to meet changing market demands and personalized consumer preferences.

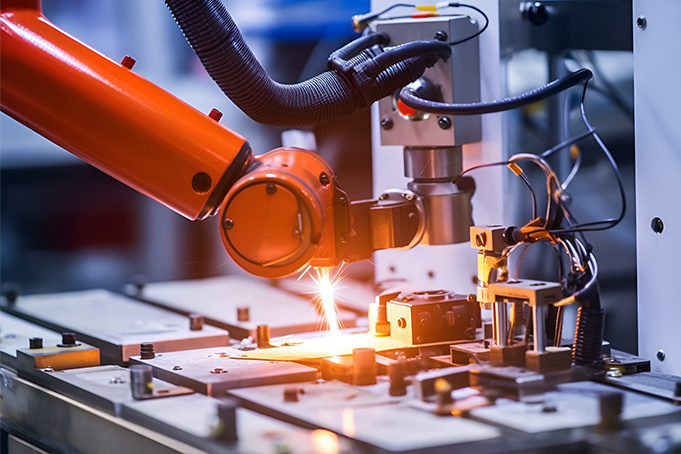

The definition of a flexible automated production management system is reflected in its ability to adapt to the needs of diversified products, quickly adjust the production line to respond to order changes, and achieve self-optimization during the production process. Such systems usually include highly integrated information technology and automation technologies, such as the Internet of Things (IoT), big data, machine learning, and robotics, which work together on the production process to improve the intelligence of operations.

The benefits of implementing a flexible automated production management system are obvious. It can significantly improve production efficiency, reduce human errors, and reduce production costs while providing higher customer satisfaction. By controlling the production process and real-time data analysis, companies can respond to market changes faster and shorten product time to market, thereby gaining an advantage in fierce market competition.

Key components of flexible automated production management systems include intelligent production scheduling systems, flexible mechanical design, configurable control software, and integrated sensors and feedback mechanisms. These components work together to ensure that the production line can switch between different products seamlessly while maintaining efficiency and high quality.

In terms of application cases, the automobile manufacturing industry is one of the industries where flexible automated production management systems are widely used. For example, some car manufacturers have adopted flexible automated production lines that can produce different models of vehicles according to demand. The application of this system not only improves production efficiency, but also greatly reduces downtime caused by model changes.

The challenges faced by flexible automated production management systems mainly include high initial investment costs, continuous investment requirements due to rapid technological upgrading, and high requirements for operator skills. To overcome these challenges, companies need to develop smart investment plans, regularly train employees on skills, and establish long-term relationships with technology suppliers to obtain timely technical support and upgrade services.

Looking to the future, flexible automated production management systems will continue to develop toward more intelligence and integration. As artificial intelligence and machine learning technologies continue to advance, these systems are expected to become more predictive of maintenance needs and production trends, further optimizing production efficiency and reducing costs. At the same time, with the popularization of technology and reduction of costs, more and more small and medium-sized enterprises will be able to use this system to improve their production capacity and market response speed.

Flexible automated production management system is a key innovation in modern manufacturing. With its unique flexibility and adaptive capabilities, it helps companies effectively respond to changing market environments. Although it faces certain challenges, the benefits far outweigh the costs and is an important force in promoting the future development of the manufacturing industry. As technology continues to evolve, flexible automated production will continue the innovation path of the manufacturing industry.

More news