Use intelligence to help you produce every step of the way

In today's fast-paced era, intelligence has become an important force in promoting productivity progress. Whether it is the robot arm on the automated production line or the data-driven intelligent decision-making system, intelligent technology is constantly optimizing the production process and improving efficiency and quality. This article will explore how to use intelligent technology to assist every step in the production process to ensure that companies can maintain their position in this highly competitive market environment.

First of all, the introduction of intelligent technology can optimize the formulation of production plans from the source. Through big data analysis and machine learning algorithms, companies can make more accurate predictions of market demand, thereby adjusting production plans and reducing inventory backlogs or out-of-stock phenomena. For example, intelligent systems can automatically adjust production volume based on historical sales data, seasonal fluctuations, and market trends to ensure resource allocation.

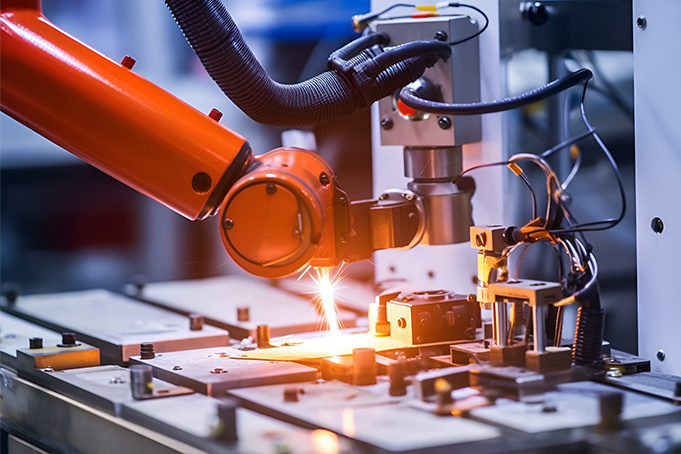

Then, in the execution stage of the production process, the intelligent manufacturing system can automatically adjust equipment parameters by monitoring the status of the production line in real time to ensure the consistency of product quality. At the same time, through machine vision and sensor technology, the intelligent system can detect production defects in a timely manner and respond quickly, reduce scrap rates, and improve resource utilization efficiency.

In addition, intelligence can also play a huge role in material management. Automated warehousing systems can accurately track the flow of raw materials and finished products, reduce logistics costs, and prevent goods from being lost or damaged. Intelligent algorithms can also optimize the supply chain, predict and respond to possible supply disruptions, and ensure the continuity of production.

Intelligent technology also demonstrates its powerful capabilities in product inspection and quality control. By integrating advanced image recognition and analysis technologies, intelligent systems can perform fast and accurate quality checks on the production line to ensure that every product meets the standards. This not only improves product quality, but also enhances consumer trust and satisfaction.

Finally, intelligent technology can also help companies provide better customer experience in product after-sales service. Using IoT technology, intelligent products can provide real-time feedback on usage data, help companies understand product performance in a timely manner, prevent potential failures, and provide remote diagnosis and maintenance services when necessary.

In summary, the application of intelligent technology is not limited to a single production link, but runs through every step of the entire production process. From production planning to execution, from material management to product inspection, and then to after-sales service, intelligent technology can bring significant efficiency improvements and cost savings to enterprises. In this era driven by data and intelligence, only by embracing intelligence can enterprises seize the initiative in the fierce market competition and achieve sustainable development.

More news