What are the workflow and advantages of real-time print labeling machines?

Real-time printing labeling machine, also called instant printing labeling machine, online printing labeling machine, are the same type of products. This equipment is also the same as other ordinary labeling machines and is widely used in electronics, packaging, logistics, supermarkets and other industries.

Working process

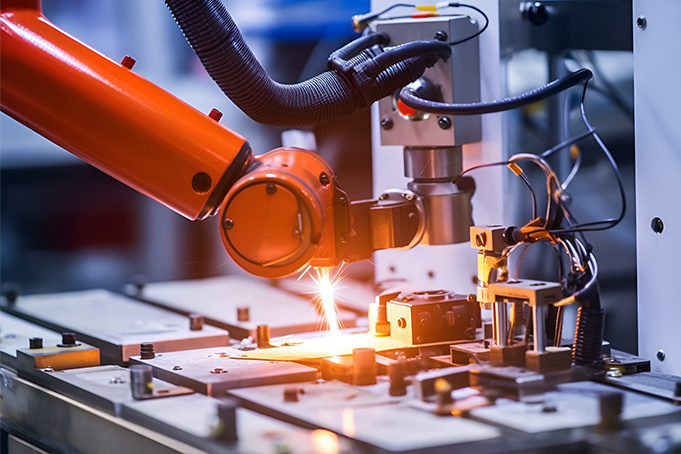

◆Core working principle: The sensor detects the product passing by and sends a signal back to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the product to be labeled. The product flows through the labeling roller, the label is rolled over, and the attachment of a label is completed.

◆Operation process: automatic product feeding—>product labeling—>product scanning—>data transmission to computer—>computer return signal identification—>automatic rejection—>automatic generation of data file storage and traceability—>automatic stacking and pushing of materials.

Features

◆Powerful functions: This equipment can realize automatic loading, automatic positioning, real-time printing and labeling, review and scanning, automatic rejection, and automatic stacking.

◆Simple matching: It can be directly installed on the assembly line and packaging machine, with independent control or linkage control to realize unmanned automatic labeling production.

◆High labeling accuracy: The label belt is guided around to prevent the label from going off track. The subdivided stepper motor drives the label output. The front and rear positions of the labels are accurate. The labeling is smooth, without bubbles or wrinkles, which improves the packaging quality.

◆Touch screen operation: The human-computer interaction interface has an operation teaching function, parameter modification is intuitive and clear, and various functions are easy to switch.

◆Intelligent control: automatic photoelectric tracking, with the functions of no-object labeling, no-label automatic correction and label automatic detection to prevent missing labels and label waste.

◆High stability: It adopts advanced electronic control system composed of Panasonic PLC + Panasonic touch screen + Panasonic pin-shaped electric eye + German Leuze label electric eye, which supports 7×24 hours continuous operation of the equipment. Attached to the position where the product is to be labeled, the product flows through the labeling roller, the label is rolled over, and the attaching action of a label is completed.

More news